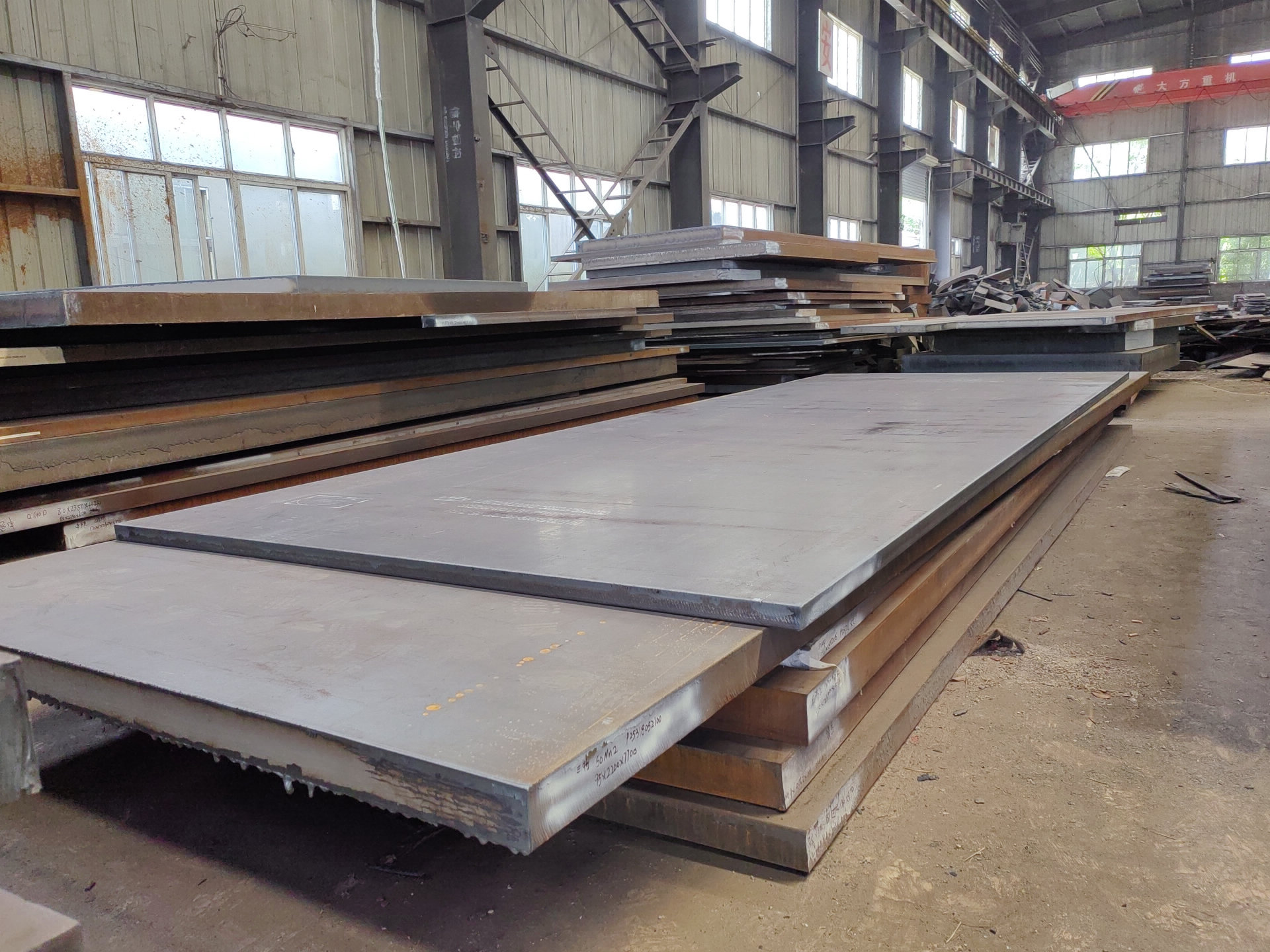

SB410

1. Brief Introduction

SB410 is a carbon steel plate for low-pressure boilers and pressure vessels, specified by the Japanese Industrial Standards (JIS). It offers good plasticity, toughness, and weldability, with mature production processes and high cost-effectiveness. It is primarily used to manufacture boiler drums, pressure vessel shells, and other pressure-bearing components operating under ambient and moderate-temperature conditions, commonly found in industries such as power generation, heating, and chemical processing.

2. Grade Designation Explanation

- S: Stands for Steel.

- B: Stands for Boiler, indicating steel intended for boilers and pressure vessels.

- 410: This number does not have a specific chemical meaning; it simply denotes a specific grade within the JIS G 3103 standard, whose specified minimum tensile strength is approximately 410 MPa. Higher strength grades like SB450 also exist in this standard.

3. Physical Properties

Typical room temperature mechanical properties of SB410 (specific values vary with plate thickness and heat treatment condition):

- Tensile Strength: ≥ 410 MPa

- Yield Strength: ≥ 245 MPa

- Elongation: ≥ 21% (depends on sample type and thickness)

- Modulus of Elasticity: Approximately 200 GPa

- Density: Approximately 7.85 g/cm³

4. Chemical Properties

Chemical composition requirements for SB410 (mass percent, maximum unless specified):

- C (Carbon): 0.24

- Si (Silicon): 0.35

- Mn (Manganese): 0.90

- P (Phosphorus): 0.035

- S (Sulfur): 0.035

The composition is designed with low carbon and moderate silicon/manganese content to ensure sufficient strength while prioritizing excellent weldability, cold workability, and toughness.

5. Application Fields

SB410 is primarily used for manufacturing welded pressure vessel structures not subjected to severe cold working. Typical applications include:

Boiler Equipment: Drums (steam drums), headers, and furnaces for low-pressure boilers.

Pressure Vessels: Storage tanks, heat exchanger shells, separators in the petrochemical industry, and low-temperature pressure vessels (provided impact energy requirements are met).

General Structures: Can be used in construction, bridges, and other steel structures requiring good weldability.

6. Testing & Production Methods

Production Method: Smelted by converter or electric furnace and delivered in hot-rolled or normalized condition.

Heat Treatment: Usually supplied in the hot-rolled (SR) or normalized (N) condition, depending on thickness and requirements.

Testing Requirements: Each batch of plates must undergo mechanical tests (tensile, bend) and chemical analysis according to the JIS G 3103 standard. Charpy V-notch impact testing can be conducted upon request. The manufacturer provides inspection certificates complying with the standard.

7. Corresponding or Similar Steel Grades

Chinese Standard (GB): Q245R. This is the most direct corresponding grade for pressure vessel plates in China, with mechanical properties and chemical composition very close to SB410, and their application fields almost entirely overlap.

European Standard (EN): P265GH. This grade is generally equivalent in application and performance level to SB410 and is a common substitute material in European standards. Sometimes it can also correspond to P295GH (slightly higher strength).

American Standard (ASTM): SA285 Gr.C. Its strength grade (Tensile Strength ≥ 415 MPa) and applications are most similar to those of SB410.

Ultrasonic Testing (UT)

A key non-destructive testing technique that uses high-frequency sound waves to detect internal flaws in steel plates. The probe emits sound waves, which reflect when encountering defects such as cracks or inclusions. The receiver captures the echoes, enabling precise determination of defect location and size. With high sensitivity, strong penetration, and fast inspection speed, UT effectively ensures internal quality, widely used in the production of heavy plates, pressure vessel plates, and other high-end products to guarantee safety and reliability.

Magnetic Particle Testing (MT)

A common surface inspection method that magnetizes the workpiece, causing leakage magnetic fields at surface or near-surface defects like cracks or inclusions, which attract magnetic particles to form visible indications. Simple to operate and highly sensitive, MT is suitable for rapid inspection of surface and near-surface flaws in ferromagnetic materials, widely used for online or offline inspection of plate edges, ends, and welds, ensuring product quality and safety.

Penetrant Testing (PT)

A non-destructive method for detecting surface-breaking flaws. A penetrant liquid is applied to the cleaned steel surface, allowing it to seep into defects such as cracks or pores. After removing excess penetrant, a developer is applied, causing the trapped penetrant to bleed out and form visible indications. Simple and cost-effective, PT is suitable for inspecting surface defects in various non-porous materials, commonly used for welds, castings, and complex components, effectively ensuring surface quality of steel plates.