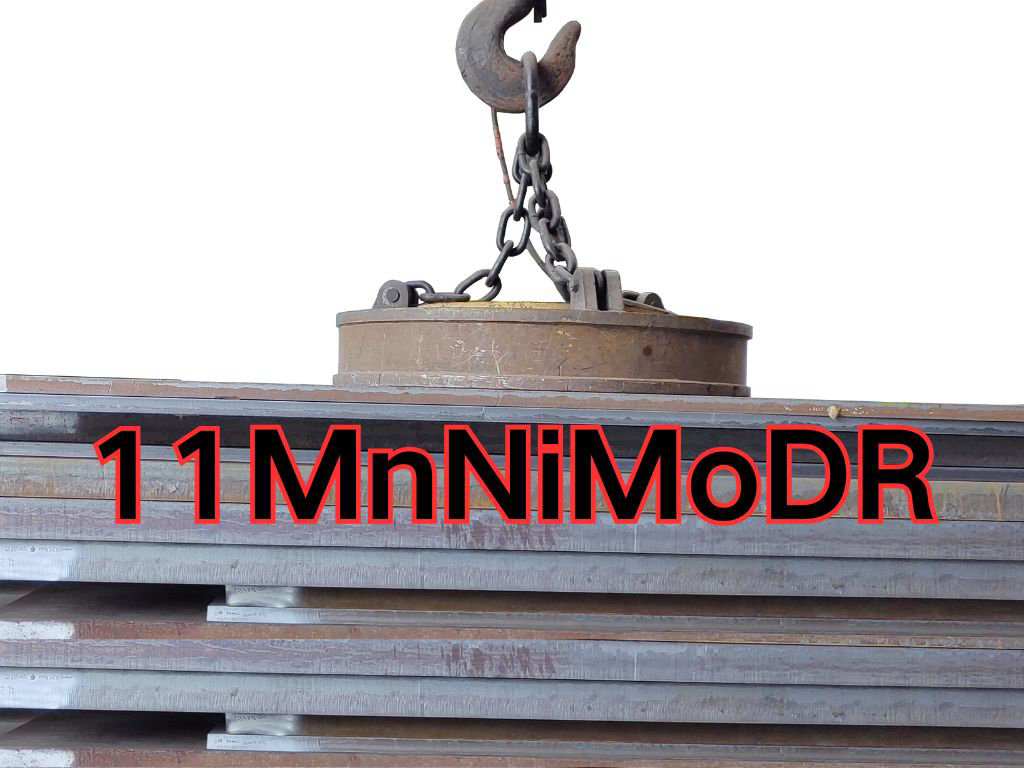

11MnNiMoDR

1) Brief Introduction

11MnNiMoDR is a low-alloy, high-strength steel plate for pressure vessels, featuring excellent comprehensive mechanical properties and weldability. It is widely used in manufacturing pressure vessels operating under medium and low-temperature conditions.

2) Grade Designation Explanation

- 11Mn: Indicates a carbon content of approximately 0.11% and the primary alloying element manganese (Mn);

- Ni: Nickel is added to improve low-temperature toughness and hardenability;

- Mo: Molybdenum enhances strength and high-temperature stability;

- D: Denotes requirement for low-temperature impact toughness (tested at -20 °C);

- R: Stands for "Rong" (Chinese pinyin for "vessel"), indicating application in pressure vessels.

This grade is specified in the Chinese national standard, GB 713.3-2023 Steel Plate, Sheet and Strip for Pressure Equipment ---- Part 3: Low Alloy Steel with Specified Low Temperature Properties.

3) Physical Properties

- Density: ~7.85 g/cm³

- Elastic Modulus: ~210 GPa (at 20 °C)

- Coefficient of Thermal Expansion: ~12×10⁻⁶ /°C (20–300 °C)

- Thermal Conductivity: ~45–50 W/(m·K) (at ambient temperature)

- Specific Heat Capacity: ~460 J/(kg·K)

The steel maintains good dimensional and thermal stability within the temperature range of -20 °C to 400 °C.

4) Chemical Composition (Typical Values, per GB 713-2014)

C: ≤0.15%

Si: 0.15–0.40%

Mn: 1.10–1.60%

Ni: 0.30–0.80%

Mo: 0.20–0.40%

P: ≤0.020%

S: ≤0.010%

Alt: ≥0.020%

Through microalloying design, the steel achieves a fine-grained structure after normalizing or normalizing + tempering, enhancing strength and toughness.

5) Application Areas

- Petrochemical Industry: Used in reactors, heat exchangers, separators, and other medium- and low-temperature pressure vessels;

- Energy Equipment: Suitable for liquefied gas storage tanks, synthesis towers, etc.;

- Industrial Boilers: Applied in pressure-bearing components for medium- and high-pressure boilers;

- Low-Temperature Applications: Safe for operation down to -20 °C, ideal for pressure vessels in cold climates.

6) Testing and Manufacturing Methods

Manufacturing Process:

Produced via oxygen converter or electric arc furnace, followed by LF refining and RH vacuum treatment to ensure high purity. After continuous casting, the slabs are reheated and hot-rolled. The plates are typically delivered in normalized or normalized + tempered condition to ensure uniform microstructure and superior mechanical properties.

Testing Requirements:

- Tensile testing (yield strength, tensile strength, elongation)

- Impact testing (V-notch Charpy impact at -20 °C, ≥34 J)

- Bend testing (180° cold bend, acceptable)

- Ultrasonic testing (per NB/T 47013, if required)

- Through-thickness (Z-direction) property testing (optional)

7) Equivalent or Comparable Grades in International Standards

Standard System Equivalent or Similar Grade Remarks

| Standard System | Equivalent or Similar Grade | Remarks |

|---|---|---|

| ASTM (USA) | A533 Gr.B Cl.1 or A542 Type A | A533 Gr.B Cl.1 is a Mn-Ni-Mo medium-thickness pressure vessel steel with similar properties; A542 Type A is a higher-strength quenched & tempered steel—selection depends on heat treatment and application |

| JIS (Japan) | SBVNII or SBV3K | SBVNII (older grade) is a Ni-Mo-Mn normalized steel for pressure vessels, closely matching performance |

| EN (Europe) | 16Mo3 (1.5415) or 15NiCuMoNb5-6-4 (1.6368) | 16Mo3 has lower Ni content and is suited for higher temperatures; 15NiCuMoNb5 offers better low-temperature toughness and corrosion resistance, making it a viable alternative |

> Note: Cross-standard substitution requires evaluation based on specific service conditions, mechanical requirements, and welding procedures. Technical agreement is recommended to confirm compatibility.

Ultrasonic Testing (UT)

A key non-destructive testing technique that uses high-frequency sound waves to detect internal flaws in steel plates. The probe emits sound waves, which reflect when encountering defects such as cracks or inclusions. The receiver captures the echoes, enabling precise determination of defect location and size. With high sensitivity, strong penetration, and fast inspection speed, UT effectively ensures internal quality, widely used in the production of heavy plates, pressure vessel plates, and other high-end products to guarantee safety and reliability.

Magnetic Particle Testing (MT)

A common surface inspection method that magnetizes the workpiece, causing leakage magnetic fields at surface or near-surface defects like cracks or inclusions, which attract magnetic particles to form visible indications. Simple to operate and highly sensitive, MT is suitable for rapid inspection of surface and near-surface flaws in ferromagnetic materials, widely used for online or offline inspection of plate edges, ends, and welds, ensuring product quality and safety.

Penetrant Testing (PT)

A non-destructive method for detecting surface-breaking flaws. A penetrant liquid is applied to the cleaned steel surface, allowing it to seep into defects such as cracks or pores. After removing excess penetrant, a developer is applied, causing the trapped penetrant to bleed out and form visible indications. Simple and cost-effective, PT is suitable for inspecting surface defects in various non-porous materials, commonly used for welds, castings, and complex components, effectively ensuring surface quality of steel plates.