CortenB

Corten B is a globally renowned high-strength weathering structural steel plate. The name "Corten" is a trademark registered by U.S. Steel, derived from a combination of the English words "CORrosion" and "TENsile strength," perfectly summarizing the core characteristics of this steel—excellent atmospheric corrosion resistance and high strength. The "B" denotes a specific grade within this series.

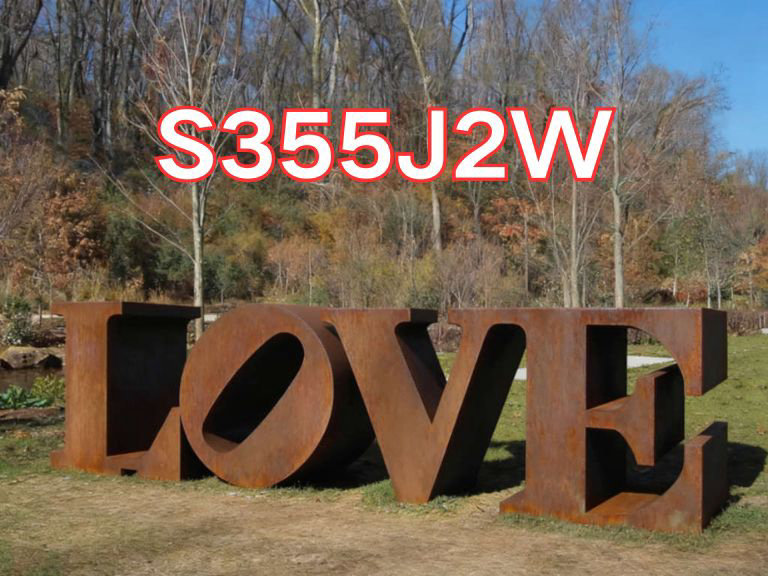

Corten B steel plate primarily conforms to the European standard EN 10025-5:2019 "Hot rolled products of structural steels—Part 5: Technical delivery conditions for structural steels with improved atmospheric corrosion resistance." In this standard, the standardized designation corresponding to Corten B is S355J0W or S355J2W, where "S" stands for structural steel, "355" indicates a minimum yield strength of 355 MPa, "J0" or "J2" represents the quality grade (specifying impact toughness requirements at 0°C and -20°C, respectively), and "W" stands for "Weathering." Additionally, it corresponds to the S355W grade in the international standard ISO 4952:2006.

The primary application of Corten B steel plate is in the construction of various buildings and engineering structures that are permanently exposed to the atmosphere. Thanks to its unique properties, it has become the material of choice for architects and engineers when designing projects with distinctive aesthetic effects and low maintenance requirements. Typical applications include:

Architecture: Used for building façade cladding, art sculptures, landscape features, and indoor/outdoor decorative panels, where its naturally formed reddish-brown rust patina is regarded as a unique industrial aesthetic.

Bridge Engineering: Used to manufacture load-bearing components such as main girders and trusses for railway and highway bridges, significantly reducing the lifecycle maintenance costs of bridges.

Transportation: Used in containers, truck bodies, and traffic signal towers.

Industrial Facilities: Used in storage silos, chimneys, piping, and platform supports.

Its main characteristics include:

Excellent Atmospheric Corrosion Resistance: By adding alloying elements such as copper (Cu), chromium (Cr), nickel (Ni), and phosphorus (P), the steel forms a dense, stable, and well-adhered rust layer in the atmosphere. This layer effectively prevents oxygen, moisture, and pollutants from further eroding the underlying base metal, causing the corrosion rate to slow down rapidly after an initial period and eventually stabilize. Its corrosion resistance is typically 4 to 8 times that of ordinary carbon steel.

High Strength: With a high yield strength of 355 MPa and good tensile strength, it meets the load-bearing requirements of structural engineering.

Maintenance-Free: In most atmospheric environments, Corten B can be used without painting, eliminating the need for regular repainting maintenance required by ordinary steel, greatly reducing long-term maintenance costs and environmental impact.

Unique Aesthetic Value: The naturally formed, uniform, and stable reddish-brown rust patina provides buildings and artworks with a distinctive and expressive appearance.

Therefore, Corten B is an advanced engineering material that integrates high performance, economic efficiency, and artistic value.

Ultrasonic Testing (UT)

A key non-destructive testing technique that uses high-frequency sound waves to detect internal flaws in steel plates. The probe emits sound waves, which reflect when encountering defects such as cracks or inclusions. The receiver captures the echoes, enabling precise determination of defect location and size. With high sensitivity, strong penetration, and fast inspection speed, UT effectively ensures internal quality, widely used in the production of heavy plates, pressure vessel plates, and other high-end products to guarantee safety and reliability.

Magnetic Particle Testing (MT)

A common surface inspection method that magnetizes the workpiece, causing leakage magnetic fields at surface or near-surface defects like cracks or inclusions, which attract magnetic particles to form visible indications. Simple to operate and highly sensitive, MT is suitable for rapid inspection of surface and near-surface flaws in ferromagnetic materials, widely used for online or offline inspection of plate edges, ends, and welds, ensuring product quality and safety.

Penetrant Testing (PT)

A non-destructive method for detecting surface-breaking flaws. A penetrant liquid is applied to the cleaned steel surface, allowing it to seep into defects such as cracks or pores. After removing excess penetrant, a developer is applied, causing the trapped penetrant to bleed out and form visible indications. Simple and cost-effective, PT is suitable for inspecting surface defects in various non-porous materials, commonly used for welds, castings, and complex components, effectively ensuring surface quality of steel plates.